Instant cement for lightweight brick adhesive and tile grout

This article is going to explore the benefits of using instant cement in lightweight brick adhesive and tile grout.

1. What is Instant Cement?

- Instant cement, also called fast-setting cement, sets and hardens much faster than regular Portland cement. Its quick setting is achieved by increasing the content of calcium aluminate or adding accelerators to the mix. It is commonly used for applications requiring rapid construction or repair, such as lightweight brick adhesive and tile grout.

Comparison Summary

Property |

Instant Cement |

Portland Cement |

Initial Setting Time |

10~30 minutes |

1.5~2.5 hours |

|---|---|---|

|

Final Setting Time |

30~60 minutes |

3~6 hours |

|

Compressive Strength |

25~40 MPa |

40~60 MPa |

|

Water-to-Cement Ratio |

0.22~0.30 |

0.35~0.50 |

|

Curing Time |

24~48 hours |

28 days |

2. Lightweight Bricks and Tiles

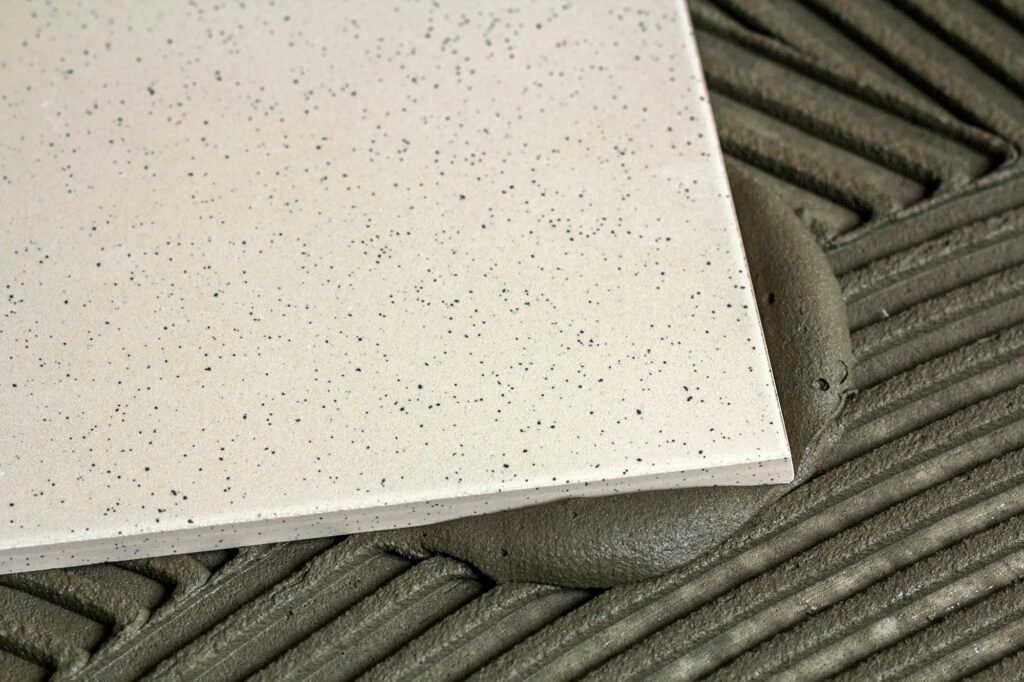

- Lightweight brick adhesive and tile grout are commonly used in lightweight bricks, such as ACC (Autoclaved Aerated Concrete) and CLC (Cellular Lightweight Concrete) blocks, and tiles, including ceramic and porcelain tiles.

- Lightweight bricks and tiles are more absorbent due to the numerous tiny pores within them. It means they are more apt to absorb water from cement mortar during construction, thus reducing bonding strength.

3. Why Use Instant Cement In Lightweight Brick Adhesive and Tile Grout?

- Lightweight bricks and tiles are porous and less dense, so they may shift or settle due to their low weight. A quick-setting adhesive ensures they stay in place without shifting or sagging.

- Both lightweight brick adhesive and tile grout are applied in thin layers, which dry out quickly if exposed to air. Instant cement ensures they are set before losing essential moisture.

- Lightweight bricks and some tiles absorb moisture quickly, which can weaken traditional adhesives or grout. Instant cement hardens faster, maintaining its strength.

- Faster-drying adhesives and grouts are preferred in urban and commercial projects, where time is crucial.

- In cold or humid environments, regular cement can take longer to dry and cure. Instant cement counters these delays, ensuring timely progress.

4. Recommend Additives for Enhancing Lightweight Brick Adhesive and Tile Grout Performance

- HPMC

- HPMC, also known as Hydroxypropyl Methyl Cellulose, is a water-soluble, non-toxic polymer additive, widely used as a water-retaining agent.

- The most important effect of HPMC is to retain moisture within the adhesive. This property allows the adhesive and grout to stay workable long enough to establish a strong bond before drying.

- HPMC also makes the adhesive easier to spread and adjust during application, which is essential for ensuring the bricks and tiles are laid evenly and securely.

- Calcium Formate

- Calcium Formate is a chemical compound often used as a setting accelerator in cement-based products. It can enhance the chemical reactions during the curing process.

- As an accelerator, Calcium formate speeds up the hydration process, a chemical reaction occurs when cement is mixed with water, binding the materials together and offering the mixture strength. This is useful in situations where a faster setting time is desired.

- By accelerating the hydration process, calcium formate can also improve the early strength of tile adhesive or grout, allowing the material to bond more quickly and securely.

5. Reference Formula of Lightweight Tile Adhesive

Materials |

Weight (%) |

Instant Cement |

30~40% |

|---|---|

|

Filler |

40~50% |

|

HPMC |

1~2% |

|

Redispersible Polymer Powder |

5~10% |

|

Calcium Formate |

0.5~1% |

|

Hydroxypropyl Starch Ether (HPS) |

0.5~1% |

The formula discussed above is intended for testing purposes only. In actual applications, customers must adjust the formulation based on the raw materials and specific project requirements. It should not be directly used for production or real-world applications.

6. LANDU: Ready to Provide Tailored Solutions for Your Unique Needs

- As a leading manufacturer of Cellulose Ether and Redispersible Polymer Powder, LANDU is always ready to offer top-quality additives and a professional expert team to achieve the best performance for your products. Explore More LANDU Chemical Additives.

- If you have any additional questions or need further assistance, feel free to reach out to LANDU for expert support.

Facebook

Twitter

LinkedIn

Telegram