- Application

- Tile Adhesive

- Wall Putty / Skim Coat

- Best EIFS Additives | Exterior Insulation and Finish System

- Drymix Mortar

- Gypsum applications

- Paints & Coatings

- Self-leveling Compounds

- Plaster Mortar

- Detergents

- Products

- Reliable HPMC Manufacturer | Hydroxypropyl Methyl Cellulose

- MHEC | HEMC Manufacturer | Hydroxyethyl Methyl Cellulose

- Hydroxyethyl Cellulose | Trusted HEC Manufacturer in China

- Professional VAE RDP Supplier | Redispersible Polymer Powder

- Sustainability

- Services

Global growth through Quality and Trends

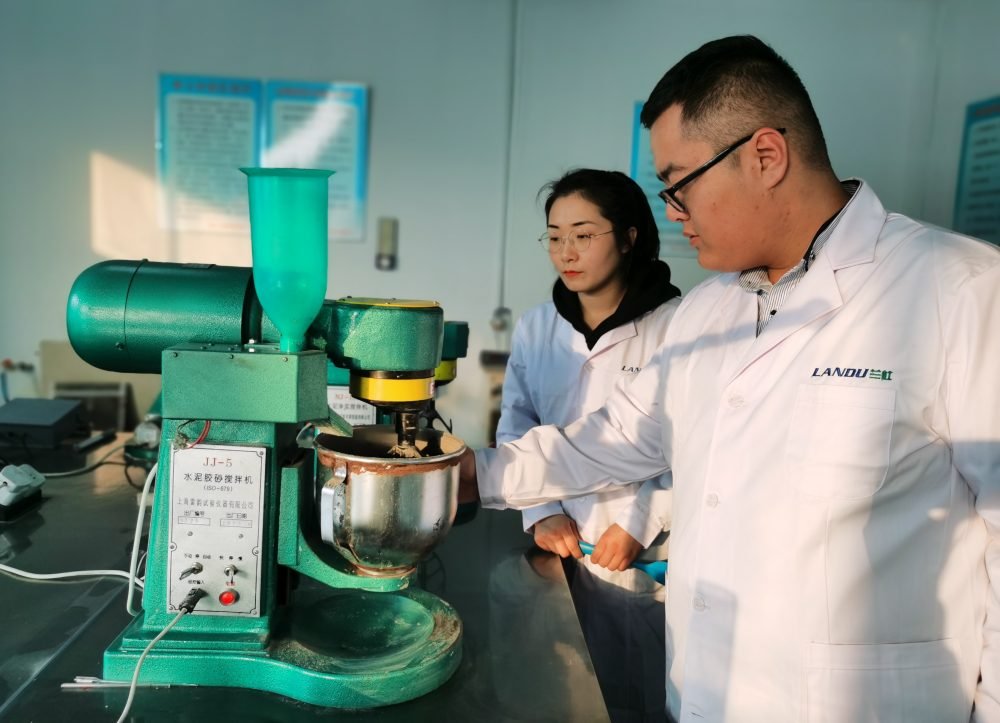

Cellulose Ether Services

We lead in cellulose technology services, offering global solution

Contract Manufacturing

We assist with powder products, providing turnkey formula processing solutions.

Formulation Development

We can customize and optimize formulas based on customer needs.

Pre-sales Service

We provide free shipping and sample charges, offering customers test samples.

After-sales Service

We provide solutions for a series of issues that arise after product sales

- Company

LANDU Global Specialty Chemicals Leader

- News & Events

Stay informed with our latest updates

News and events

News and events

Expert Industry Insights

- Contact